Class Time During the last couple of months, IAS has held motor control classes for Shaw Electricians. Not only is the material good for electricians to know, our licensed electricians also receive Continuing Education Units for attending the classes. They need 18 hours of CEU’s every 3 years to maintain their state electrical licenses.Classes have been held in Davenport, Waterloo, and New London. Instruction included basic motor control circuit elements, hands on building of control circuits, schematics, troubleshooting, and safety. Below, Adam Fraise (far left) troubleshoots a motor controller that Stephen Mahieu (standing) has created a ‘problem’ in. Kurt Wagner (left) and Nathan Burden (right) watch as Adam does his troubleshooting. If you have questions about CEU classes, contact Dan Freeman. Ken Deering...

Learn MoreSun’s Coming Up! With solar system prices coming down and electricity rates going up, most folks are seeing solar photo-voltaic systems popping up around Iowa and Illinois. And IAS/Shaw Electric are there to provide quality installations for our solar customers. Here are two solar warriors, Mark Johnson on the left, Josh Thola on the right, braving the wet and cold December, at an array they just installed. Not shown is Cecil Becerril, as he only showed his backside to the camera. Mission accomplished, Cecil. How big of system would you need to supply your electrical needs? Call IAS. We can assess your current and future needs, and size a system to fit your needs. We can also show you what your financial returns will be, so you plan your investment accordingly. If you, or you know someone or some business or organization considering a solar electric system, let us know. We’ll be happy to discuss options and possibilities. IAS/Shaw Electric can bring quality solutions for solar energy systems. Let the sun start working for you! Ken Deering...

Learn MoreThe Other Web IAS and Shaw Electric have teamed up for another large controls job lately. This one isn’t the World Wide Web, it’s a web tensioning application for a local industry. What is web tensioning, you may ask? It is the process of pulling a flexible product, coming off a manufacturing process, through a series of rollers and winders, all the while maintaining just the right amount of tension on the web of material so it doesn’t break or get balled up. This is not as easy as you may think. Mike Truninger, above, also wired controls. Josh Kruse, the mastermind of the project, is on the right. He did the engineering and integration work. Mark Johnson, on the left, wired the controls, and Josh Cozad in the center performed field wiring for the motors and control wires. Tyler Mills, right, also performed field wiring. Not shown are Shaw Project Manager Eric Holst, Supervisor Lee Luett, who, out of respect for my camera, declined to be photographed, Bob Portz, Matt Jensen, and James Greer. The project came in on schedule and on budget, with process startup in progress. Well...

Learn MoreThe Next Generation With a new year upon us, it’s a good time to celebrate things new. New challenges, new technologies, and new customers. It’s especially gratifying to see new people interested in the engineering and design professions. Our business and our country need the next generation of engineers and technicians to bring the next generation of ideas to life. Those ideas are critically important to keeping our industries productive and competitive and healthy. Pictured above left is Edgar, an engineering student intern who is back to work on a project over his Christmas break. Edgar is helping us complete an engineering study for a customer that has an end-of-year deadline. To the right is Tyler, Al Glover’s son, who is a high school junior. He’s interested in a technical career, and wanted to spend a day with us seeing what a day in the life of an engineer is like. Tyler got a chance to talk with Edgar about school, internships, and what made him decide on an engineering career path. Tyler also got a chance to talk with our Jimmy Skadal about what its like for an engineer new to the field, and what engineering means to him. It wasn’t all talk for Tyler, however. I put...

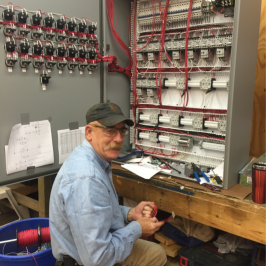

Learn MoreDesigns and deBuilds When our customers need electrical panels designed and/or built, they come to our experts at IAS. Here, Mike Truninger is building a control panel for an ethanol plant. This panel will control gates on a new DDG handling system, allowing the customer to drop DDG into a number of different bins, while controlling which bin is being filled from the ground. Above, Steve Garthaus, our design drafter, is standing next to designs he created for another panel shop in town for motor control centers. In the cabinets Steve designed are variable frequency drives, motor starters, breakers, operator screens, and the like. In this case our customer will be able to show their customers what the finished product will look like, and build the motor control centers from these designs. Steve continues to learn and grow in his job, and bring value to our company and our customers. That’s a win-win! Please tell your customers that IAS can bring designs and control panels to them to address their control system needs. Ken Deering...

Learn MoreControl A Shredder When businesses want to destroy sensitive documents, they shred them. In this case, the industrial shredder that is getting new controls actually shreds raw material so it can be made into new product. Here, Jimmy is programming the industrial control computer, on the right. The industrial computer is called a PLC, or programmable logic controller. He’s also programming the operator interface, called an HMI, which you can see on the computer screens. Industrial computers like this scan their sensors hundreds of times a second, and depending on what it sees, it performs the logic that Jimmy has programmed and controls the machine accordingly. Our readers have experience with PLC’s in their daily lives. There is a small version of this type of computer in your car. It controls the car depending on its inputs, sensing your gas pedal position, for example. These computers are robust, fast, and dependable. No wonder auto manufacturers and industrial customers rely on them. In this case, Jimmy is going to replace an existing PLC and operator screens that have been in service for many years. The new PLC and HMI’s will serve our customer for many years to come. Please tell your customers that IAS can bring total design, programming,...

Learn More